Digital Manufacturing: Onwards to 2018

If you were waiting all year for the big digital manufacturing revolution and subsequent manufacturing renaissance, don’t worry you didn’t miss it. While it’s true that U.S. manufacturing output and employment have risen significantly over the last year, this is more the product of overall economic health and less the result of any wide adoption of a new manufacturing ethos.

New paradigm shifts in manufacturing are rare and driving change in manufacturing takes a good bit of time. But whether it’s 5 years from now, 10 years, or 20 years, digital manufacturing is where we are heading and you should be thinking about what you’re doing to prepare your business for it. Adopting digital manufacturing techniques today is playing offense. If you wait too long, you’ll be playing defense.

The Digital Manufacturing Framework

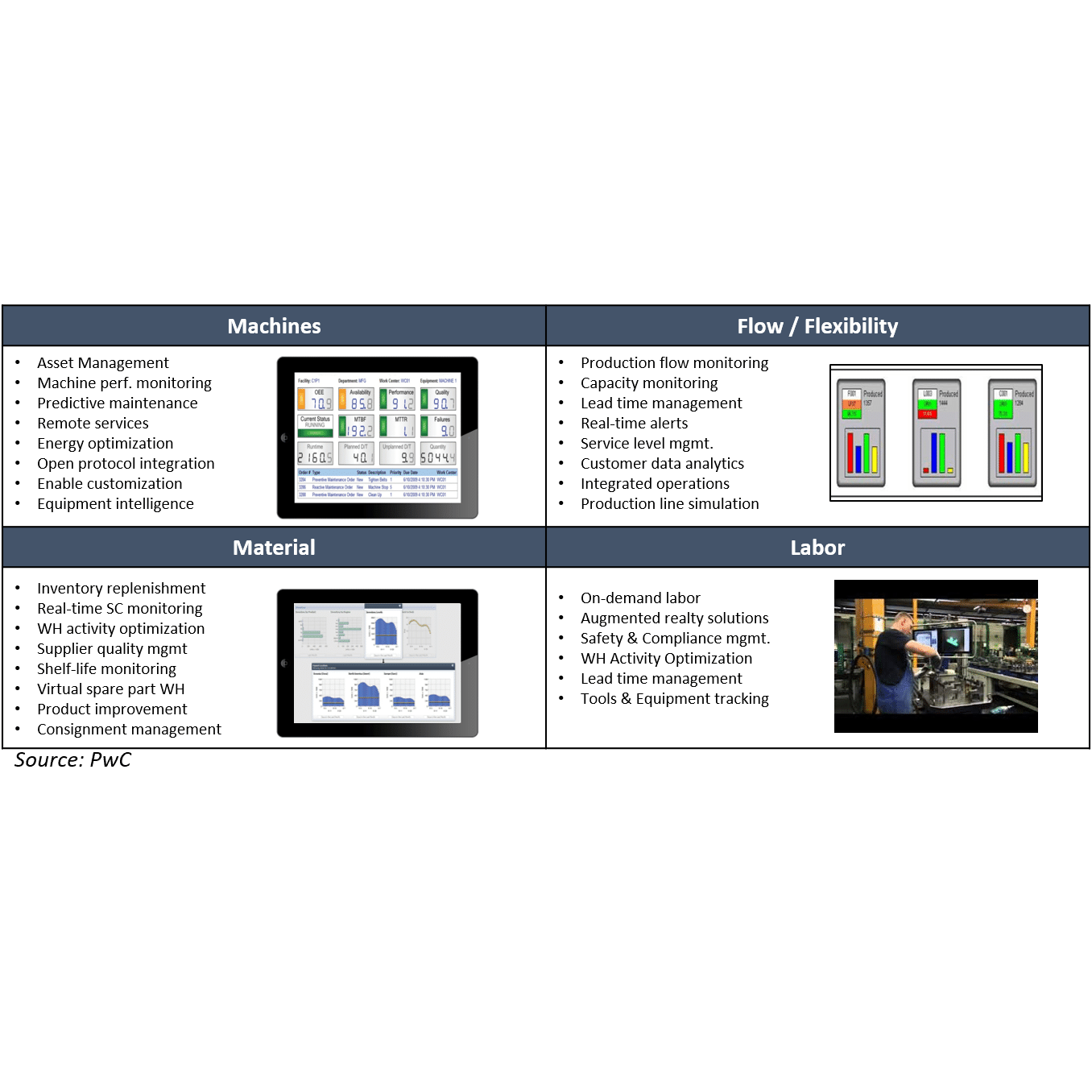

In this blog, we will overlay a couple of these frameworks to orient use cases evolving in today’s landscape. Any time you hear about an emerging manufacturing technology, it will likely fall into one or more of four general categories of use cases:

- IoT / Connected Factory – operational intelligence, big data, analytics, etc.

- Automation – robots, cobots, factory control, etc.

- Additive Manufacturing – 3D printing, etc.

- Workforce Enablement – on-demand labor, augmented reality, haptics and optics, etc.

In addition, each of these use case categories derives value by impacting what we call four manufacturing focus areas:

- Machines – predictive maintenance, OEE, asset productivity, etc.

- Materials – inventory optimization, materials availability, etc.

- Flow / Flexibility – bottleneck optimization, real-time production monitoring, etc.

Labor – labor productivity, production flexibility and agility, etc.It’s important to consider both of these dimensions when evaluating the digital manufacturing landscape since only through the two combined can you build a business case that links technology to use case to value creation driver to value created.

Where do we stand at the end of 2017?

With few exceptions, we approach the end of 2017 in the same place we were a year ago. This should come as no surprise to most – manufacturing as a sector is stubborn and conservative. It’s difficult to drive meaningful and lasting change, and doing so requires the coordination among many stakeholders, inside and outside the four walls of the factory, as well as solution design, implementation planning, and the allocation of capital.

So we stand today with an idea of what the future looks like and a general understanding of the technologies and use cases that enable the future vision. The following table gives some examples of those use cases.

The fact of the matter is that manufacturing change takes time and the value creation mechanism has to be clear. Implicitly, everyone knows that each of these use cases could create tremendous value but the level of uncertainty around implementation requirements, time to value, vendor selection, etc. has led to another year of general stagnation.

What should we expect in 2018?

Until there are tangible case studies and demonstrated value in the marketplace, expect the digital manufacturing revolution to continue to make only modest gains. From our vantage point, the pace is being stalled by a preoccupation with the most difficult use cases: those involving machine intelligence and central IT infrastructure.

It’s an odd place to start due to the difficultly of implementation but it’s also no surprise that this is the case. The providers of machine-oriented IoT based solutions like GE, Siemens, Rockwell Automation, etc. are the same OEMs with an existing installed base and have been first to market solutions.

The large tech companies with cloud based operational intelligence platforms are also in the game but lack the installed base at the equipment level. The fastest way to drive large scale adoption is to refocus on the primary sources of value like labor productivity and growth enablement. At Veryable, we believe that labor flexibility should be the tip of the spear that subsidizes other value add use cases as illustrated in the figure below.

For most manufacturers, the most productive way to think of machine and flow oriented use cases is to view them as enablers for higher labor productivity and throughput. Starting with labor will put the business case in your hands and the rest will follow logically.

Previous Posts

How Policy Constraints, Not Just Production Bottlenecks, Threaten Your Bottom Line

The Future of Manufacturing and Logistics

Create a free business profile today to explore our platform.